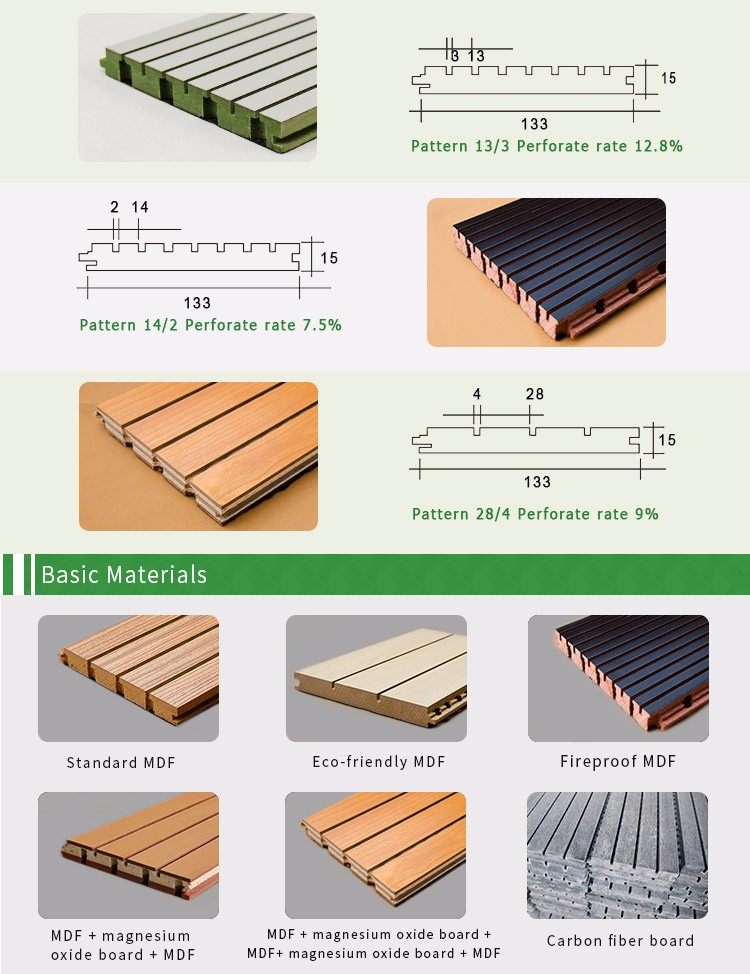

1> Grooved acoustic panel is a kind of slit resonance absorption material which is made from high density

panel with grooves on the surface and perforated holes at the back side.

2> It has strong selection on the sound spectrum and particular great performance on the middle and

low frequency.

3> It has better sound absorption effect on medium and high frequency if there is sound absorption cotton

filled at the back side cavity.

4> The design can be custom made

5> How to calculate the perforated rate:

1) When the hole line up in square P=0.785*(D/B)m2

2) When the hole line up in Equilateral triangle

P=0.907*(D/B)m2

P ----- Perforated rate(%)

D ----- Diameter of the hole

B ----- Distance between two center of the holes

1> The grooved acoustic panel is made of high quality MDF board.

2> According to the customer’s acoustic and decoration requirement, our MDF board can equipped with

outstanding environmental, flame retardant and waterproof function, even can with various colors and

finish choices.

3> Our grooved acoustic panel’s highest fire retardant grade can reach A2(GB) grade, and the best environmental

protection can reach E1(GB) grade.

4> Grooved wood acoustic panel structures’ finish including: Melamine, Natural veneer, Anti-fire plate, Paint,

Metal sheet, Artificial veneer and leather etc.

5> Acoustic tissue including: The black color and attached at the back side of acoustic panel tissue, has fire retardant

and sound absorption function.

| PRODUCT SIZE |

| width | 133mm 197mm |

| length | 2440mm |

| thickness | 12mm 15mm 18mm |

allowance : width ±1mm , length ±2mm , thickness ±0.2mm |

Sendinquiry soon>>

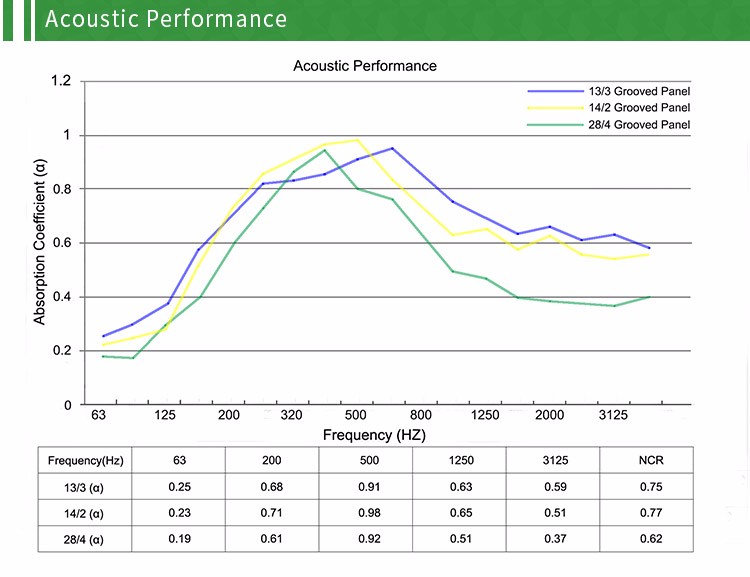

Acoustic absorption is usually defined in terms of an absorption coefficient (usually denoted by the Greek letter alpha, α),

defined as the ratio of absorbed to incident sound energy from a single interaction between a sound wave and a certain

material.

Absorption coefficients range from 0 to 1 and vary with frequency,

α=0 means that the material absorbs no sound and reflects all sound energy incident on it.

α=1 means that the material absorbs all sound energy incident on it and reflects none.

Absorption coefficients of 0 and 1 are ideal values that do not exist in reality because all materials reflect and absorb some sound.

In general, materials having absorption coefficients less than 0.15 are considered to be reflective and those having absorption coefficients greater than 0.4 are considered to be absorptive.

As you can see our Testing report show that our products have a very good performance in a large range of application.

Send inquiry soon>>